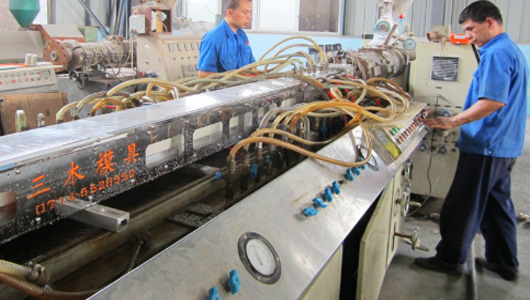

I. Precautions for mold maintenance

1. Regularly disassemble, clean, and maintain the flow channel, and check its flatness;

2. During disassembly and cleaning, it is important to protect the sharp corners of the mold lip and the runner. If there are minor damages or nicks, consult a professional for guidance;

3. Never use hard tools such as steel to clean the flow channel and sealing area to avoid damage;

4. Conduct electrical safety inspections to ensure timely replacement of any damaged equipment;

5. Check the sealing surface for flatness;

6. Check the fastening screws to see if they are securely tightened;

II. Mold Maintenance

1. Scratches on the surface of the die lip, product drawing, adjustment of flatness, replacement of heating elements, addition of die lip, core rod, and flow resistance device

2. Maintenance and upgrading of old mold heads, including the repair, upgrading, and transformation of old mold heads, such as the removal of main screws, mold maintenance, replacement or modification of fine adjustment device components, comprehensive renovation of the mold head, and electroplating, to restore the performance level of the old mold head to that of a new one.

III. Pre-ordered parts reservation

We provide users with all parts services in the industry, maintain inventory of all standard spare parts, including spare parts for old products, and customize various non-standard accessories.

For ordering and parts inquiries, please contact our technical service team.

+086-0714-6528552 +086-0714-5374588